TECHNOLOGY

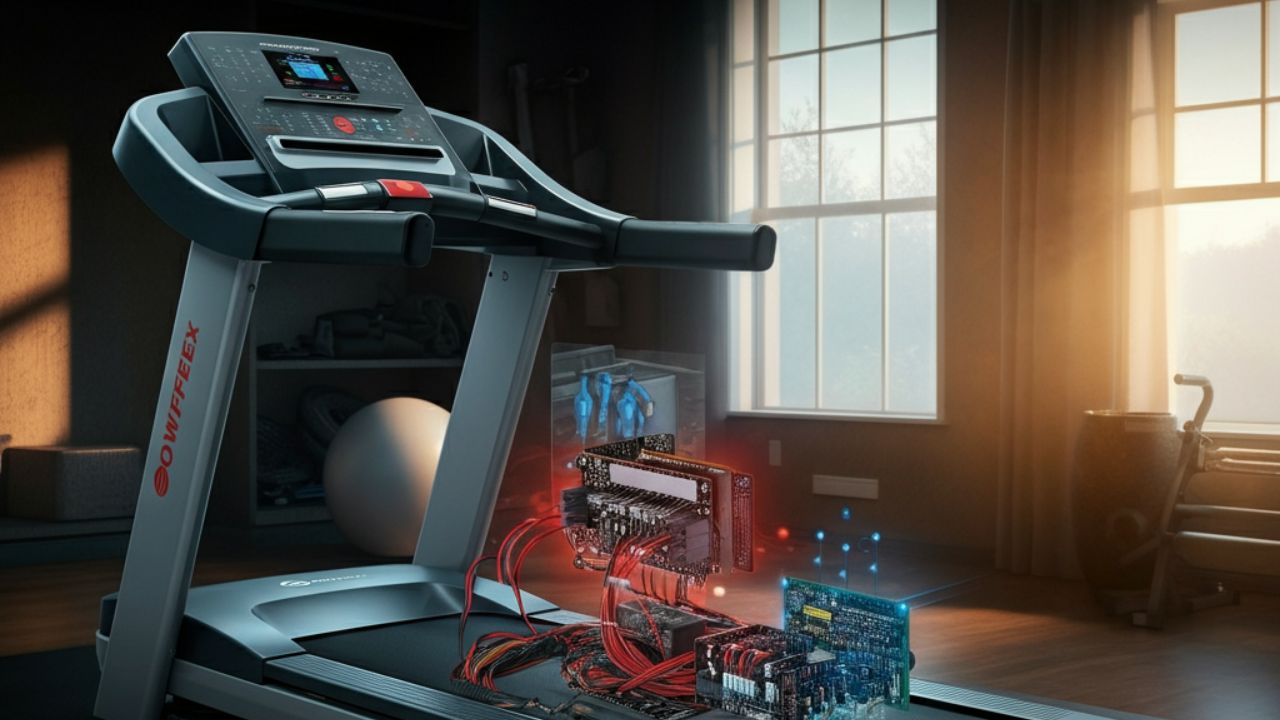

Bowflex TC 3000 Hot Wire Power Supply: Step-by-Step Guide to Installation and Repair

Are you experiencing issues with your Bowflex TC 3000 hot wire power supply? Whether you’re setting it up for the first time or tackling a repair, this guide has you covered. Maintaining your Bowflex TC 3000 Hot Wire Power Supply is essential to ensure it keeps delivering high-performance workouts. This blog provides a clear, step-by-step guide to help you install, troubleshoot, and repair the hot wire power supply efficiently.

By the end of this guide, you’ll not only understand how your machine’s power system works, but you’ll also gain skills to keep it running smoothly for years to come.

Understanding the Bowflex TC 3000 Hot Wire Power Supply

Before jumping into installation and repair, it’s important to understand the role of the hot wire power supply. The Bowflex TC 3000 relies on this essential component to distribute power and keep the console, resistance settings, and other electrical parts functioning optimally.

The hot wire power supply ensures:

- The treadmill base receives stable electrical current.

- Display functions like heart rate tracking and workout settings operate smoothly.

- Safety mechanisms like shut-off protocols remain active.

If this component fails or isn’t installed correctly, your Bowflex TC 3000 may experience interruptions in operation, displaying errors on the console or shutting down entirely.

Why Do Power Supply Issues Arise?

Power supply problems in the Bowflex TC 3000 are usually linked to one of the following causes:

- Loose connections between the wires and terminals.

- Voltage inconsistencies in your home’s power outlet.

- Wear and tear over time, especially if used in a high-humidity setting.

- Use of an incompatible or damaged power cord.

Step-By-Step Guide to Installation of the Hot Wire Power Supply

To help you avoid common pitfalls, here’s a carefully structured guide for a hassle-free installation.

Step 1: Gather the Tools You’ll Need

Before you begin, gather the following tools and equipment for an efficient installation process:

- A screwdriver set

- Electrical tape

- Wire connectors

- Voltage meter (recommended for testing connections)

Ensure you are working in a well-lit area and have easy access to the Bowflex TC 3000’s power connection points.

Step 2: Turn Off the Power

Safety comes first! Unplug your Bowflex TC 3000 from the wall outlet to ensure there’s no active current running through the machine while you work. Double-check this step to avoid electric shock.

Step 3: Locate the Power Connection Panel

Find the power connection panel at the base of your Bowflex TC 3000. Use your screwdriver to gently open the panel. You’ll find the hot wire terminal where the power supply connects to the machine’s internal wiring.

Step 4: Connect the Wires

- Begin by identifying the correct wire configuration provided in your user manual. Typically, the hot wire is red, while the neutral wire is black.

- Secure the wires to the appropriate terminals using the wire connectors. Make sure the connections are snug and not loose.

- Wrap any exposed wires with electrical tape to prevent accidental contact.

Step 5: Test the Voltage Output

Using a voltage meter, test the power supply output to ensure it matches the voltage requirements listed in the Bowflex TC 3000 manual (usually around 120V for most regions).

Step 6: Close the Panel and Turn It On

Once everything checks out, close the connection panel using your screwdriver. Plug in the machine and power it on to confirm functionality. Check for any error messages on the console.

Troubleshooting Common Issues

If your Bowflex TC 3000 isn’t working as expected after installation, here are quick fixes for common problems:

Issue 1: Display Screen Won’t Turn On

Solution: Ensure the power cord is securely plugged in. Test the outlet by plugging in another device to confirm it’s working.

Issue 2: Error Code Displayed on Console

Solution: Refer to the Bowflex TC 3000 user manual for error code descriptions. Commonly, power-related errors point to loose or incorrect wire connections—double-check these.

Issue 3: Machine Stops Mid-Workout

Solution: Test for overheating. If the power supply feels hot to the touch, turn off the machine and allow it to cool down. Ensure the ventilation around the base is unobstructed.

Repairing a Faulty Hot Wire Power Supply

Sometimes, a power supply issue may require more than troubleshooting. Here’s how to address repairs effectively.

Step 1: Diagnose the Problem

Use a voltage meter to test whether the power supply is delivering consistent voltage. A reading below the expected voltage indicates a fault.

Step 2: Inspect for Damage

Open the power supply panel and look for:

- Burns or scorch marks on the wires.

- Frayed or exposed wiring.

- Loose components, such as screws or connectors.

Step 3: Replace the Faulty Components

If you identify any damaged wires or connectors, replace them with components recommended by Bowflex. You can purchase these through official suppliers or verified third-party retailers.

Step 4: Test the Repaired Power Supply

After replacing the damaged parts, reconnect everything as per the installation guide above. Power on the machine to ensure the issue is resolved.

When to Consult a Professional

If you’re unable to fix the issue or feel uncomfortable dealing with electrical repairs, it’s best to call a certified technician. Attempting complex repairs without the proper knowledge could void your warranty or cause further damage.

Tips for Maintaining the Bowflex TC 3000 Power Supply

Extend the life of your power supply with these simple maintenance tips:

- Avoid Overloading the Circuit: Always plug your machine into a dedicated outlet to prevent power surges.

- Keep the Area Clean: Dust and debris can accumulate around the power connection panel, causing overheating.

- Store Properly: If you’re storing your Bowflex TC 3000, unplug it and store it in a dry, cool location.

Keep Your Bowflex TC 3000 Running Smoothly

Your Bowflex TC 3000 is an investment in your health and fitness, and keeping its power supply in good condition is key to long-term performance. Whether it’s through installation, troubleshooting, or repairs, a little attention can go a long way in avoiding disruptions to your workout routine.

If you’re unsure about any part of the process or need professional support, reaching out to Bowflex’s customer care team is always a smart option.

Now that you’re equipped with all the knowledge you need, why not take a moment to ensure your machine is functioning at its best? Regular checks and maintenance will keep your Bowflex TC 3000 ready to power your fitness goals for years to come.

TECHNOLOGY

Amikaf16: The Future of Modern Technology in Daily Life

Technology has become an indispensable part of how we live, work, and connect. From mobile banking to smart homes, every passing generation of innovation seems to amplify the convenience and efficiency of our daily lives. Enter Amikaf16—a modern marvel poised to redefine how we interact with technology forever.

What makes Amikaf16 so special? In this blog, we’ll explore what sets it apart and discuss its revolutionary potential across various aspects of daily life, such as communication, healthcare, education, and home automation.

If you’re curious about how a single advancement could seamlessly integrate into every facet of your day-to-day routines, read on.

What is Amikaf16?

Amikaf16 is not just another piece of software or hardware. It’s a multifunctional platform powered by advanced AI (Artificial Intelligence) and IoT (Internet of Things) technologies, designed to serve as a centralized hub for personal and professional life management.

With its state-of-the-art intelligence, Amikaf16 not only adapts to your individual habits but also uses predictive analytics to anticipate your needs before you even realize them. Its applications range from managing your digital communication to automating your home appliances—all with unparalleled efficiency.

But its promise doesn’t stop there. Amikaf16 is wired for scalability, meaning its capabilities will evolve with new updates, ensuring that it remains a cutting-edge solution as times change.

Why Does Amikaf16 Matter?

Today’s technological landscape is disparate—separate devices to handle separate needs. But Amikaf16 serves as the unifying layer that connects all these fragments, creating a more cohesive and seamless operation. Imagine a world where your smartwatch, smartphone, thermostat, fridge, and even your health records communicate perfectly with one another.

The result? Effortless control, boundless connectivity, and significant time savings. Let’s dive into its impact on key aspects of life.

How Amikaf16 Will Transform Key Areas of Your Life

1. Intelligent Communication

Communication tools often feel cluttered—between emails, texts, and video chats, things can get overwhelming. Amikaf16 promises to declutter this process by acting as a personal assistant for all communication channels.

- Centralized Messaging: Instead of toggling between apps (WhatsApp, email, SMS), Amikaf16 consolidates messages into one space.

- AI-Powered Responses: It learns your communication style, offering accurate, on-brand suggestions for replies, saving you time and reducing errors.

- Voice and Gesture Commands: Forget typing. Using simple voice or gesture commands, you can seamlessly take calls, check missed messages, or draft emails.

2. Revolutionizing Healthcare

Amikaf16 will move beyond wearable health trackers by integrating with hospitals and pharmacies to act as your personal health concierge.

- Health Monitoring: Using connected IoT devices, Amikaf16 tracks your vitals, offering comprehensive reports on heart rate, blood sugar, and more.

- Doctor Appointments: Need a check-up? Its smart scheduling feature suggests the best times based on your calendar and confirms appointments with healthcare providers.

- Medication Reminders: Never forget another pill—Amikaf16 uses gentle prompts and stores an up-to-date prescription record accessible anytime.

3. Smarter Learning and Education

For students and lifelong learners alike, Amikaf16 offers personalized learning pathways tailored to how individuals retain information best.

- AI-Driven Tutors: Struggling with algebra? The AI can break concepts down into digestible, interactive lessons.

- Global Classroom Access: Join live lectures or workshops from top universities with a single voice command.

- Time Management: From assignment deadlines to exam prep, Amikaf16 structures your schedule to maximize productivity.

4. Automation in Home Life

Imagine waking up to freshly brewed coffee, with the temperature adjusted to your liking and soft music playing in the background. With Amikaf16, this isn’t just a dream.

- Home Automation: Control your lights, thermostat, curtains, and TVs all from one interface.

- Energy Efficiency: By learning your preferences, Amikaf16 optimizes energy usage, reducing your bills and your carbon footprint.

- Groceries on Autopilot: Running low on milk? Amikaf16 syncs with your smart fridge and places orders for you.

5. Personalized Marketing and Shopping

Tired of poorly targeted ads? Amikaf16 curates suggestions based on your actual needs and preferences.

- Tailored Recommendations: It analyzes your recent searches and purchases, ensuring highly relevant suggestions.

- Effortless Checkouts: Integrated with major retailers, Amikaf16 automates checkouts and tracks your shipment progress in real-time.

Amikaf16 and Privacy Concerns

A question that comes to mind for many users is, “How secure is my data?”

Amikaf16 prioritizes user privacy with end-to-end encryption across all its connections. Furthermore, you have full control over what data the platform collects and stores, ensuring transparency every step of the way.

Advanced biometric verification ensures that only authorized users can access sensitive features like healthcare updates or financial transactions.

What Makes Amikaf16 Stand Out?

Unlike other AI solutions that focus on singular applications, Amikaf16 is an all-encompassing innovation, integrating AI, IoT, and user-specific personalization into one sleek package. Here’s why it leads the pack:

- Intuitive Interface: Even technology novices can use Amikaf16, thanks to its user-friendly design.

- Limitless Integration Potential: Compatible with most brands and devices, ensuring smooth adoption.

- Adaptive Learning: Grows with your lifestyle and preferences, continually improving over time.

How Enterprises Are Leveraging Amikaf16

While individuals benefit from Amikaf16, enterprises are also taking full advantage of its functionalities. From streamlining supply chains to powering customer service chatbots, businesses use Amikaf16 to boost efficiency and gain competitive advantages.

With its multi-user support and unmatched scalability, Amikaf16 is setting the gold standard for AI-driven business innovations.

How to Get Started with Amikaf16

Are you ready to experience technology’s next big leap? The future is here, and it’s wrapped in the convenience and innovation of Amikaf16.

Getting started is simple. Install the Amikaf16 starter app, customize your dashboard, and join a community of forward-thinkers already harnessing the power of this breakthrough technology.

The age of connected living and intelligent systems isn’t the future—it’s here now, and Amikaf16 is leading the charge.

TECHNOLOGY

How Risk Adjustment Vendors Support Seamless Integration of Concurrent Coding and Prospective Risk Adjustment

The evolving demands of healthcare documentation and reimbursement often leave organizations grappling with how to align real-time data capture with forward-looking planning. For many, combining concurrent coding with prospective risk adjustment offers the dual benefit of ensuring accurate, immediate documentation and proactive care planning. However, achieving this integration is not without its challenges. This is where risk adjustment vendors step in as critical partners, offering the tools, training, and expertise needed to create cohesive workflows that drive both clinical and financial success.

Challenges of Integrating Concurrent Coding and Prospective Risk Adjustment

Healthcare providers face several obstacles when attempting to merge concurrent coding and prospective risk adjustment:

- Fragmented Workflows: Real-time documentation and predictive planning often function as separate processes, leading to inefficiencies and missed opportunities for optimization.

- Technological Disparities: Legacy systems and disjointed electronic health record (EHR) platforms make data integration difficult.

- Staff Adaptation: Clinicians and coders may struggle to adapt to new tools and workflows, especially when balancing documentation with patient care.

- Compliance Risks: Misaligned processes increase the risk of regulatory non-compliance, resulting in potential audits and financial penalties.

Risk adjustment vendors are uniquely positioned to address these challenges, enabling organizations to fully leverage the synergy between concurrent coding and prospective risk adjustment.

How Risk Adjustment Vendors Facilitate Integration

Risk adjustment vendors play a pivotal role in bridging the gap between real-time documentation and predictive planning. Here’s how they support seamless integration:

- Unified Technology Solutions

Vendors provide platforms that bring concurrent coding and prospective risk adjustment under one umbrella. These systems integrate seamlessly with existing EHRs, ensuring a unified workflow that minimizes manual effort and maximizes accuracy. By combining real-time coding with predictive analytics, these tools create a comprehensive view of patient data, enabling organizations to capture every relevant diagnosis and treatment.

- Tailored Training and Support

Successful integration requires more than just technology—it demands a workforce equipped to use it effectively. Risk adjustment vendors offer tailored training programs for both clinicians and coders, helping teams understand how to document in real time while leveraging predictive insights. Hands-on support ensures a smooth transition and fosters confidence in new workflows.

- Workflow Optimization

Vendors analyze existing documentation processes to identify inefficiencies and bottlenecks. They provide data-driven solutions that streamline workflows, ensuring that concurrent coding and prospective risk adjustment complement each other without redundancy. This holistic approach reduces administrative burden while enhancing overall productivity.

- Compliance Assurance

With ever-changing regulations, staying compliant is a top priority for healthcare organizations. Vendors ensure that integrated workflows align with regulatory standards, reducing the risk of audits and penalties. Their expertise in risk adjustment coding ensures documentation accuracy, protecting organizations from potential compliance pitfalls.

The Benefits of Partnering with Risk Adjustment Vendors

Integrating concurrent coding with prospective risk adjustment offers significant advantages, and partnering with vendors amplifies these benefits:

Improved Accuracy

Vendors equip organizations with tools that enhance the precision of documentation and coding. Predictive analytics flag potential gaps or inconsistencies in real time, ensuring that no detail is overlooked. This level of accuracy is critical for generating accurate risk scores and maximizing reimbursements.

Enhanced Efficiency

Streamlined workflows save time and reduce the administrative burden on healthcare teams. By automating routine tasks and eliminating redundancies, vendors enable clinicians and coders to focus on higher-value activities, such as patient care and complex documentation.

Optimized Financial Outcomes

Accurate and comprehensive documentation directly impacts reimbursements. With vendor support, organizations can ensure they capture all reimbursable services and align risk scores with patient complexity. This not only improves cash flow but also provides financial stability in an increasingly value-driven healthcare environment.

Better Patient Outcomes

Real-time and proactive documentation enhances care coordination, enabling clinicians to make informed decisions based on comprehensive data. This dual approach leads to more personalized care plans, better management of chronic conditions, and improved overall patient outcomes.

Overcoming Integration Challenges with Vendor Support

Despite the clear benefits, integrating concurrent coding with prospective risk adjustment can present challenges. Risk adjustment vendors offer targeted solutions to address these obstacles:

- Technology Compatibility

Integrating new tools with existing systems can be daunting. Vendors specialize in creating platforms that work seamlessly with current EHRs and other documentation systems, ensuring a smooth implementation process.

- Staff Adaptation

Adapting to new workflows can be challenging for healthcare teams already stretched thin. Vendors provide robust training programs and ongoing support to help staff build confidence and proficiency in integrated processes.

- Cost Constraints

Budget limitations are a common concern, especially for smaller organizations. Vendors offer scalable, cost-effective solutions tailored to organizational needs, ensuring a high return on investment without overextending resources.

Actionable Steps for Leveraging Vendor Support

To successfully integrate concurrent coding and prospective risk adjustment, healthcare organizations should take the following steps:

- Evaluate Current Processes

Conduct a comprehensive assessment of existing workflows to identify inefficiencies and gaps. This will help determine where vendor support can have the greatest impact.

- Choose the Right Vendor

Select a vendor with a proven track record in integrating concurrent coding and prospective risk adjustment. Look for partners who offer customizable tools, industry expertise, and a commitment to long-term support.

- Implement Tools and Training

Collaborate with your chosen vendor to deploy integrated technology solutions and provide targeted training for your team. Ensure that both clinicians and coders understand how to use the tools effectively.

- Monitor and Optimize

Use analytics to track the performance of integrated workflows. Regularly review metrics such as documentation accuracy, reimbursement rates, and compliance outcomes to identify areas for improvement and refine processes accordingly.

Conclusion

Healthcare organizations face mounting pressure to deliver accurate documentation while optimizing financial and patient outcomes. The integration of concurrent coding and prospective risk adjustment offers a powerful solution to these challenges, but successful implementation requires the right tools, training, and support.

Risk adjustment vendors play an essential role in facilitating this integration, providing the expertise and resources needed to create seamless workflows that enhance accuracy, efficiency, and compliance. By partnering with a trusted vendor, healthcare organizations can confidently navigate the complexities of modern documentation and unlock the full potential of these complementary strategies.

In today’s evolving healthcare landscape, embracing the dual approach of concurrent coding and prospective risk adjustment is not just a step toward better documentation—it’s a strategic move toward sustainable success.

TECHNOLOGY

Homelite UV80522 Drain Plug Location and Its Importance

Imagine the efficiency of your Homelite UV80522 Drain Plug Location pressure washer, the steady hum as it blasts through grime and dirt, making everything in its wake spotless. Now, imagine that same machine falling short of expectations, simply because of a small yet vital component—the drain plug.

This unassuming part plays a crucial role in your pressure washer’s maintenance and longevity. But where exactly is the drain plug located on your Homelite UV80522, and why is it so important? Let’s explore this integral feature, its purpose, and why knowing its location could save you significant cost and effort.

Why the Homelite UV80522 Drain Plug Location Matters

Every machine has its unsung hero, and for pressure washers, the Homelite UV80522 Drain Plug Location is one of them. It serves as the gateway for draining old oil, ensuring your equipment runs smoothly and efficiently. Oil degrades over time, collecting debris and becoming less effective. Proper oil drainage allows fresh oil to enhance the functionality of your pressure washer while preventing costly damage.

Neglecting this simple step can lead to long-term consequences such as engine wear, overheating, and even permanent mechanical failure. Evidently, this small plug holds the weight of your machine’s performance and longevity squarely on its proverbial shoulders.

Locating the Drain Plug on the Homelite UV80522

Finding the drain plug on the Homelite UV80522 isn’t as complicated as it may initially seem. Picture bending over the pressure washer, eyes scanning its intricate components. Your hands gently maneuver the machine to get a better look—it’s almost like discovering a treasure hidden beneath a map of metal components.

Step 1: Identify the Model

First, double-check that your pressure washer is indeed the Homelite UV80522. The model information is usually printed on a sticker near the engine or the frame. This ensures the steps that follow align with your specific machine.

Step 2: Position the Pressure Washer

Place the pressure washer on a flat, stable surface to avoid spills and potential accidents. Tip it slightly backward, just enough to reveal the underside of the pump. This is where the magic begins.

Step 3: Look for the Drain Plug

The drain plug on the Homelite UV80522 is located near the oil tank and underneath the machine. It’s usually a small, hexagonal bolt that blends effortlessly into the design of the washer. While its inconspicuous nature might make it tricky to spot initially, a flashlight can come in handy to illuminate its placement.

Step 4: Confirm the Seal

Once you’ve located the drain plug, check for a tight seal. The plug should sit firmly in place to prevent any leaks during operation but should also be easy enough to unscrew with a wrench when it’s time for an oil change.

Now that you’ve unlocked the secret of the location, it’s time to understand the steps for effective use of this little wonder.

How to Use the Drain Plug for Maximum Efficiency

Step 1: Gather Essential Tools

Before you begin, ensure you have a wrench, an oil collection pan, and replacement oil recommended in your user manual. Taking a few minutes to gather these tools will set you up for a seamless process.

Step 2: Drain Old Oil

Carefully unscrew the drain plug using your wrench, allowing the used oil to flow into the collection pan. Picture amber drops falling steadily, signaling the end of your engine’s previous oil cycle. This simple act is like a therapeutic reset for your pressure washer.

Step 3: Seal and Refill

Once the old oil is completely drained, replace the plug securely to prevent leaks. Then, add fresh oil, ensuring you don’t overfill. Turn the machine on for a few seconds to allow the new oil to circulate fully.

The Lifesaving Benefits of Regular Maintenance

Like a fine-tuned symphony, your Homelite pressure washer performs at its best when every part, no matter how small, is in perfect harmony. Regular oil changes via the drain plug have an array of benefits, such as:

- Enhanced Performance: A well-oiled engine works harder and lasts longer.

- Extended Lifespan: Routine maintenance reduces wear and tear, ensuring years of reliable service.

- Cost Savings: Preventative care is always more affordable than costly repairs or full replacements.

By incorporating this practice into your maintenance routine, you’re safeguarding the longevity and efficiency of your pressure washer for the long haul.

Troubleshooting Common Drain Plug Issues

Even the most reliable components can pose challenges. But fret not—each problem has a practical solution.

- Issue 1: The plug is stuck.

- Solution: Apply a penetrating oil to loosen it, or use a specially designed drain plug removal tool.

- Issue 2: The plug is leaking oil.

- Solution: Check that it is tightened properly. Replace the washer seal if necessary.

- Issue 3: Oil won’t drain completely.

- Solution: Slightly tilt the pressure washer forward to assist in full drainage.

Understanding and resolving these issues can minimize downtime, keeping your Homelite UV80522 in peak condition.

Why Trust the Homelite UV80522?

From blasting stubborn dirt off driveways to preparing surfaces for a fresh coat of paint, the Homelite UV80522 is an unrivaled cleaning companion. Its thoughtfully designed components, such as the drain plug, exemplify the machine’s commitment to delivering superior performance while making maintenance convenient.

Owning this tool means you’re not just investing in clean driveways and outdoor spaces—you’re investing in a piece of equipment that has your back in the long run.

Keep Your Pressure Washer in Prime Condition

Congratulations! You’ve now uncovered the vital role of the Homelite UV80522’s drain plug. By knowing its exact location and understanding how to use and maintain it, you’re well on your way to getting the most out of your pressure washer.

Regular maintenance ensures that every blast of water it delivers is powerful and reliable, speaking volumes about your commitment to quality and care.

For more tips, tricks, and tools to help maintain your equipment, stay tuned to our blog. If you still have questions about maintaining your Homelite UV80522, feel free to reach out. We’d love to help keep your machine working like new for years to come.

-

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoTronics 0RUL1108 Bluetooth: The Future of Wireless Technology

-

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoBE78N-S7J-E Unveiled: A Deep Dive into Its Features and Benefits

-

TECHNOLOGY10 months ago

TECHNOLOGY10 months agoTop 10 Must-See Posts from v3rb1son.tumblr You Can’t Miss!

-

TECHNOLOGY11 months ago

TECHNOLOGY11 months agoThe Benefits of a High-Speed Broadband Internet Connection for Home and Business

-

TOPIC11 months ago

TOPIC11 months agoThe Story Behind 1-617-693-7201: A Comprehensive Analysis

-

TOPIC11 months ago

TOPIC11 months agoEU-NENCFZS8 Explained: What You Need to Know for 2024

-

TECHNOLOGY12 months ago

TECHNOLOGY12 months agoHow Harwalk Info Labs is Revolutionizing the Tech Industry

-

TECHNOLOGY11 months ago

TECHNOLOGY11 months agoThe Future of Gaming Unveiled at DashGameFest 2023